The recent massive introduction of small unmanned aerial vehicles (UAVs) brought the problem of the absence of reliable aerodynamic data and models for propulsion systems that work at low Reynolds numbers. At the same time, the new capabilities of modern measuring equipment permit detailed experimental investigations of the aerodynamic characteristics of such systems. The most accurate method is the test mechanisms in which all values in which thrust and torque do not affect each other are obtained correctly. Here, the system measures the thrust and torque with the load cell and the most accurate results are obtained with other environmental sensors.

What is propeller and motor testing?

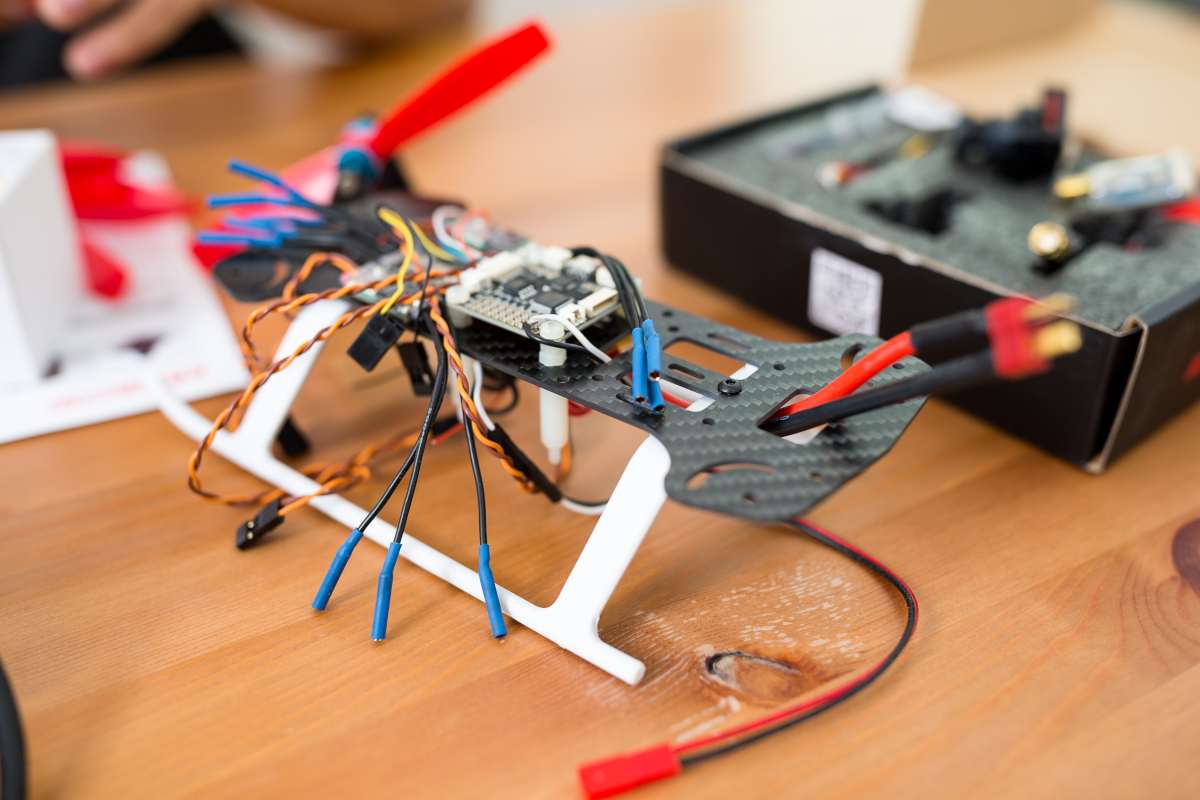

A brushless motor and propeller test stand is used to test brushless motors and propellers. This testing instrument is still only available in research laboratories.

Is it necessary to test the Motor and Propeller?

There are many domestic and foreign unmanned air manufacturer companies in the world. However, since these organizations do not have the means to test the engine-propeller tests in the UAVs they make, they try to do these efficiency tests using primitive methods or they try to create an engine-propeller combination based on the datasheets of the engines or propellers they have purchased. This is also insufficient and actually more costly. This is because the UAVs crash to the ground during the flight trials made many times for the test, which leads to high cost losses as the engine, propeller, esc and various materials are damaged and become unusable.

• Increasing the flight time, range and payload capacity

• Recording diagnostics

• Safety, certification and quality assurance

• Preventative maintenance

• Noise and vibration testing

• Thermal testing of drone motors

• Characterizing the throttle response

• Solving in-flight icing issues

What procedures are applied during the motor and propelier test?

First, the engine and propeller to be tested are selected. ESC compatible with the engine is determined. Power supply is connected to motor and ESC. The propeller to be tested is attached to the end of the motor. We start the test by protecting ourselves safely. By looking at the data coming to our computer, thrust, torque, current, voltage, accuracy etc. values are examined. According to the report result, the most suitable engine and propeller are selected for our drone, taking into account the engine and propeller efficiency.

What are the parameters that need to be measured in the motor and propeller test?

-Brushless motor efficiency

-Propeller efficiency

-Global system efficiency

-Power coefficient (Cp)

-Thrust coefficient (Ct)

-Torque coefficient (Cq)

-Advance ratio

To fully characterize a motor, you need to measure the following parameters.

• Voltage (V)

• Current (A)

• Throttling input (%)

• Engine load or torque (Nm)

• Speed (rev)

The output speed is function of the throttle, in %, and of the load, torque in Nm. If you want to completely characterize a motor, you will need to test it with multiple input voltages and different loads. The throttle is changed with the software, and the load is changed with the type and size of propeller.

Notice that the mechanical power is the same for the motor and propeller. That is because all the motor’s mechanical power output goes into the propeller, since it is directly coupled to the motor’s shaft.

Which test stand should I test the motor and propeller with?

With the Dynotis test bench, you can easily perform your engine and propeller tests. You can easily perform your tests with the USB data transfer cable for the computer, the motor mount and the required RPM and motor temperature sensors. You can perform your tests as static and dynamic (on-car test). After obtaining your data in csv form at the end of the test, you can choose the most suitable engine and propeller by examining the engine and propeller efficiency.